CP Mask: This mission for the nation, Part 10 is accomplished by 5 weeks, free mask factory.

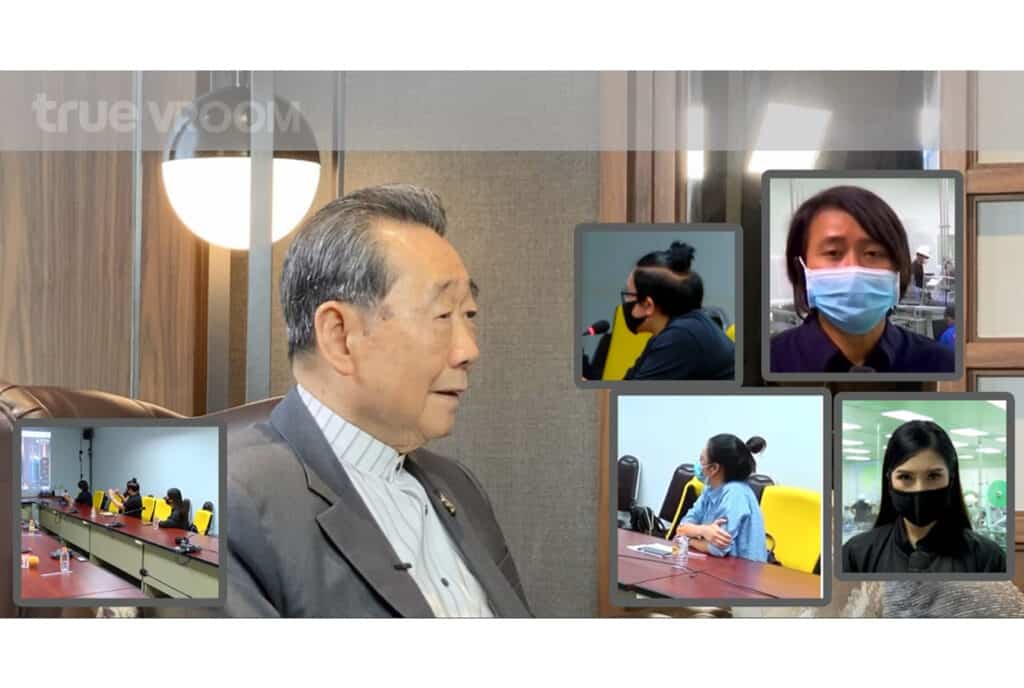

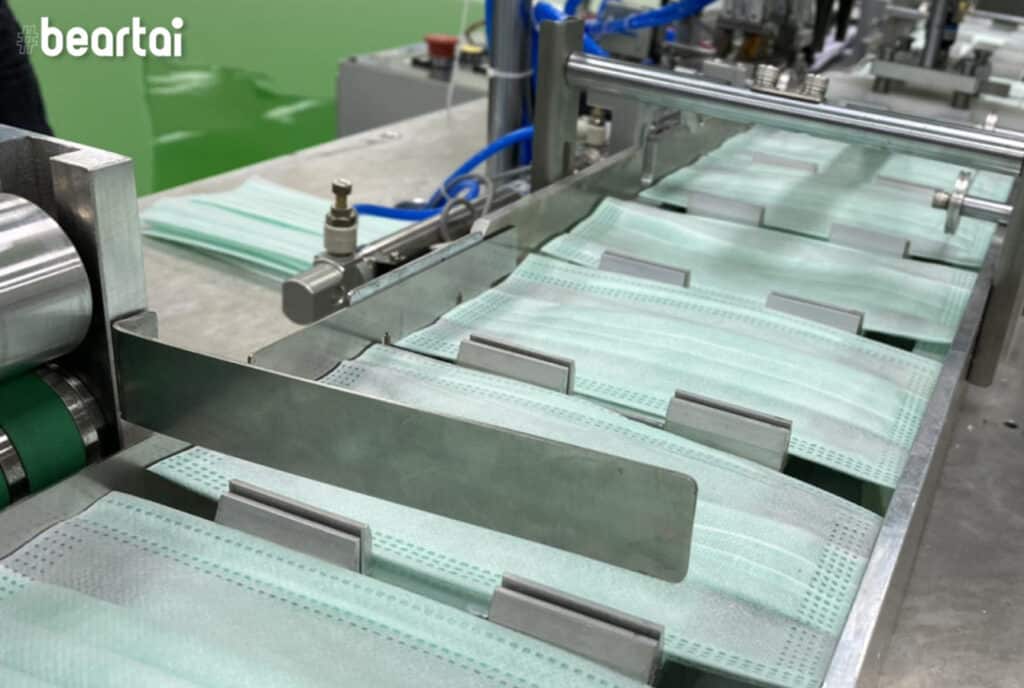

Free face mask factory For medical personnel and the public, expected within 1 week, ready to distribute through Chulalongkorn Hospital To hospitals and medical personnel across the country Successfully completed within 5 weeks on April 10, 2020. Senior President Thanin Chearavanont announced his thanks to the team. That made the mission to build a factory to produce free hygienic masks for Thai people. of Charoen Pokphand Group Completed, on schedule for 5 weeks to produce face masks. Investing more than 100 million baht, aiming to give 3 million pieces per month to medical personnel as the first group through Chulalongkorn Hospital, Thai Red Cross Society, senior president of CP, confirmed the distribution of masks. Must be performed by a doctor CP specializes in production. But who will know What medical personnel are needed? Must have the doctor distribute CP and receive guidelines. and will support it to the utmost, along with increasing production capacity To be sufficient to help Thai people Ready to ask for help fighting COVID-19 disease to win quickly and prepare to open a business After the crisis has passed In order for Thailand to be the first country to recover its economic situation […]