How important is ventilation in the silo tank?

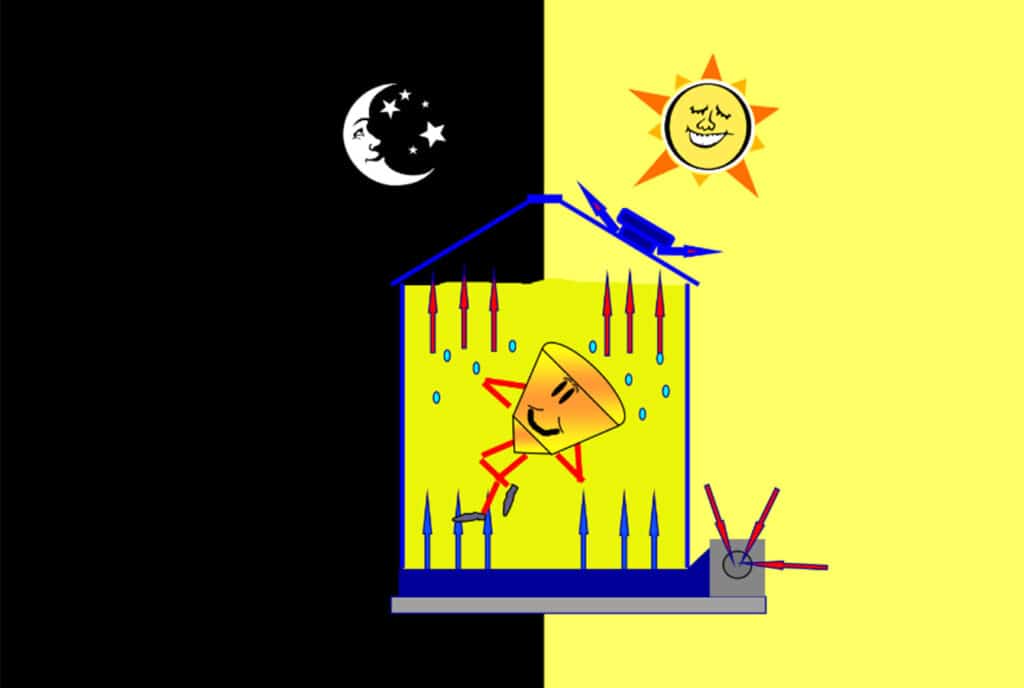

A: Why is silo ventilation required? B: Because stored raw material seeds such as corn, rice, and beans are still alive and have the ability to breathe and dehydrate, if they are planted they will still be able to grow. In addition, ventilation in the silo tank helps prevent moths and mold caused by heat and humidity. A: Why must ventilation in the silo tank be done? B: Reasons for ventilating the silo tank It is to keep the raw materials in a dry state. according to the desired conditions so that there is no fungus and insects to grow To manage constant humidity Manage the temperature evenly and creates maximum storage efficiency. However, the ventilation of the raw materials in the silo tank It does not make the properties of the raw material seeds better than before. But it will help maintain the existing properties of the raw material seeds for a longer time. A: When is it necessary to ventilate the inside of the silo tank? B: When wanting to adjust the temperature inside / outside so that it is not very different. Or adjust it to the same level (5-9 degrees) when a hot spot occurs inside the silo tank. A: What is the purpose of ventilation inside the silo tank? B: To maintain a uniform temperature of the corn kernels with an average temperature range of +/- 2° to 5° C during the day/night during […]

How important is ventilation in the silo tank? Read More »