Yawap Greenhouses Inverter system Have it and make the most of it, part 1

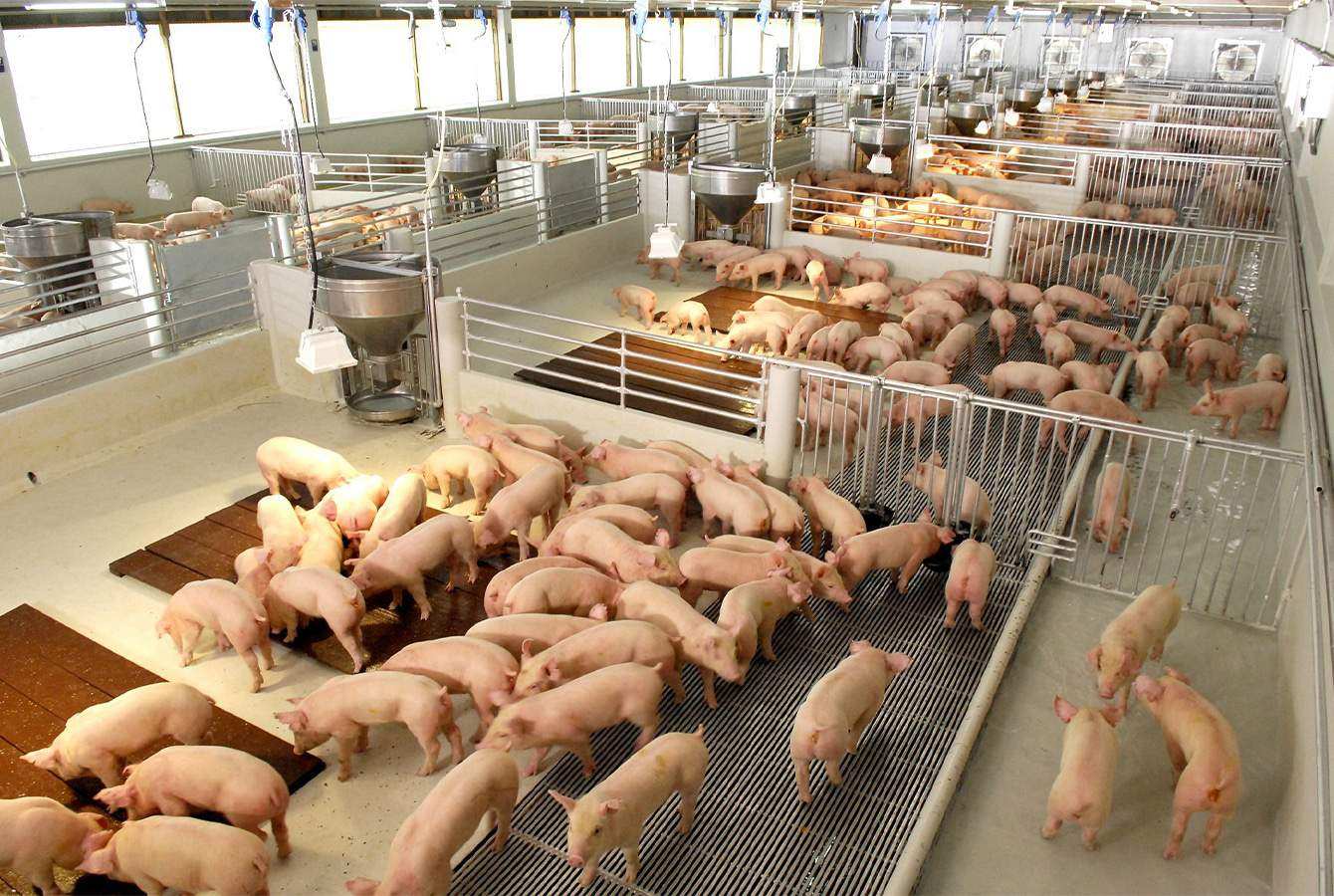

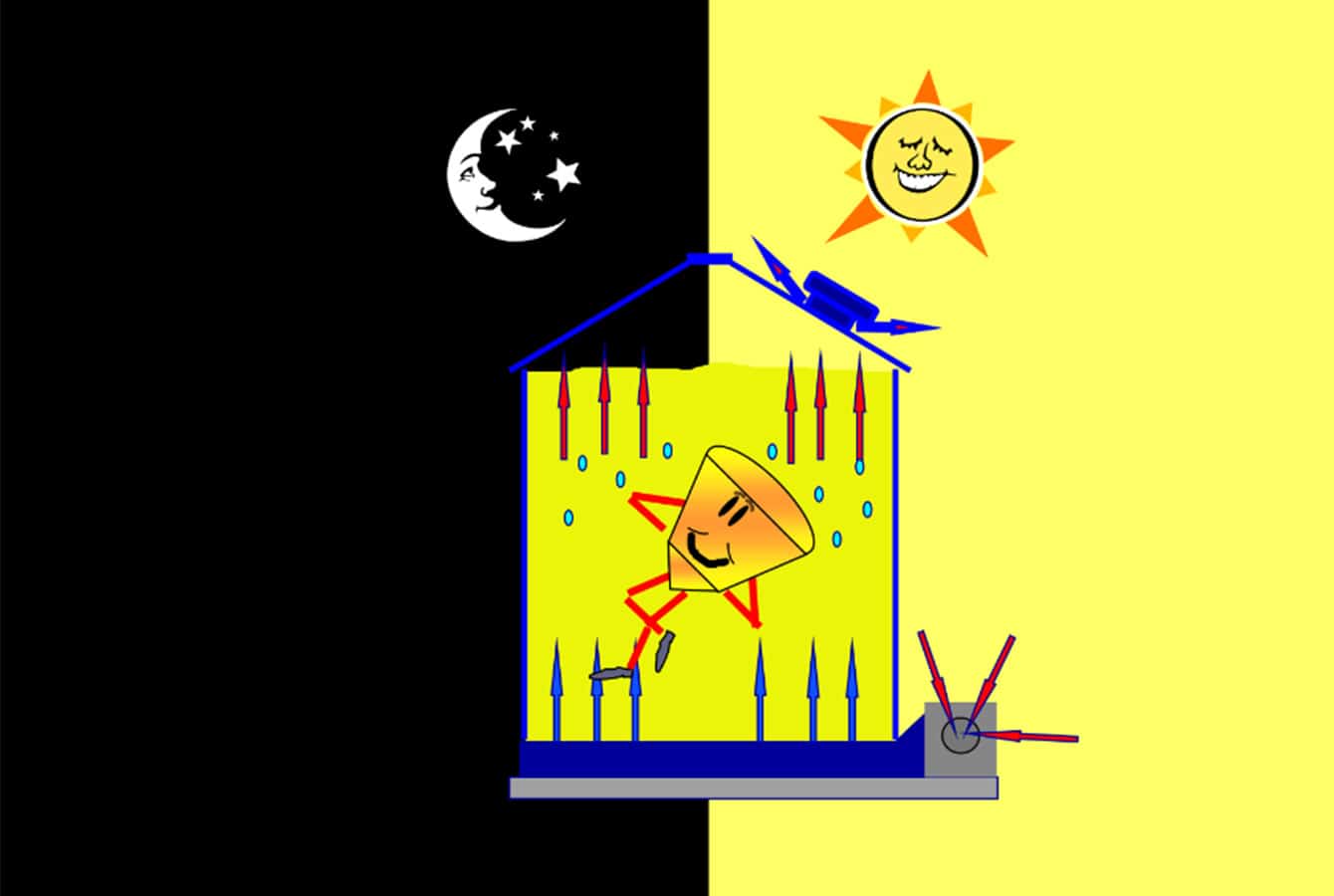

It is believed that the pig farmers who have the EVAP system. Most of the fan speed is controlled with an inverter system. Will there be any that are actively used to full efficiency? If we own a farm and use the inverter by ourselves But still not working properly according to the potential of the system You can use this article as a guide. If it is an investor who hires animal husbandry to control, it can use this article to check the knowledge and understanding of the faithful children at the level and increase their knowledge and ability to use them to their fullest potential as investors have already invested in equipment Content credits Thank you: CPF Feed Solution can read more, click!

Yawap Greenhouses Inverter system Have it and make the most of it, part 1 Read More »